Source/Courtesy of Stöckel Grinding Machines

We are often asked these and other questions at trade fairs and during customer visits. After all, stone is not the first construction material that is associated with mechanical precision engineering. Here we explain why this million-year-old rock is the ideal basis for our precision machines using 5 properties of granite.

#1 THERMAL PROPERTIES

The low linear expansion coefficient of granite is generally considered to be a particularly favorable thermal property. In fact, compared to steel and gray cast iron, the rock only expands about half as much when the temperature increases.

The thermal conductivity of granite, which is only about 1/10 of the value of the metallic construction materials mentioned, is at least just as advantageous for the construction of precise grinding machines. This makes granite-based machines extremely stable against short-term external temperature changes and thus immediately leads to more precise grinding results over a longer period of time.

#2 CUSHIONING

Just like the thermal characteristics, the special damping properties of granite are advantageous in the construction of high-precision processing machines. The material damping of this rock is approx. 10 times higher than that of commonly used steel and cast materials. When operating a grinding machine, this dampening of vibrations is primarily reflected in the higher surface quality that can be achieved and lower tool wear.

Even though the damping of the entire system depends not only on the materials used, but also on the design of the joints, by using granite as a base material we are literally laying the foundation for our high-quality precision machines.

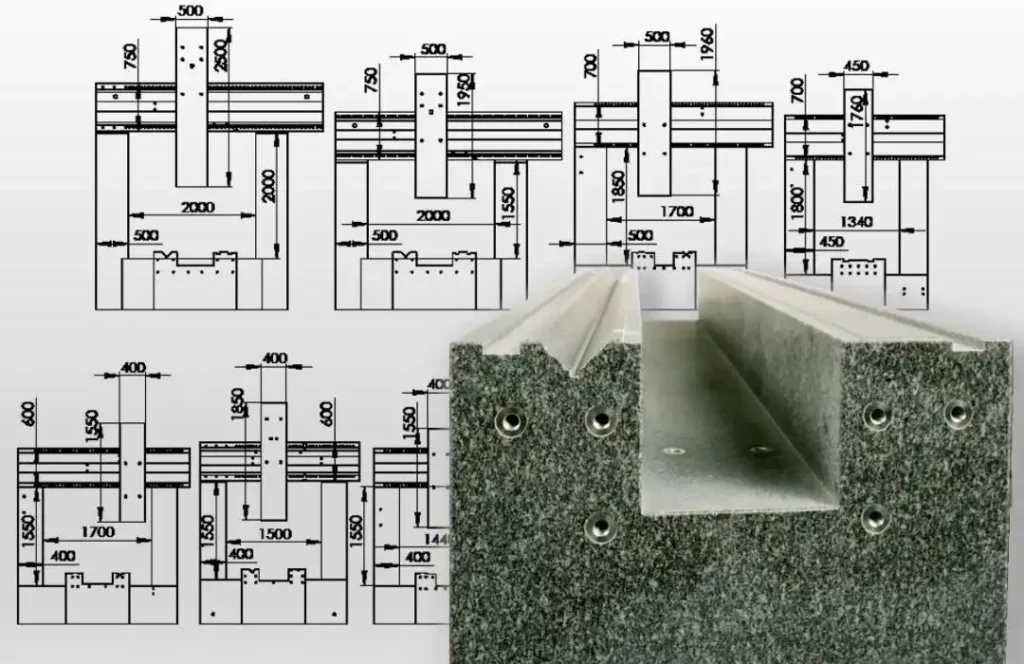

#3 FREE DESIGN

A property of granite that has less to do with physical constants than with creativity and handwork is the free design of the raw material. When designing our machines, we are not tied to existing casting models, but can adapt each machine individually to its intended use if necessary. This means that individual pieces and special machines can also be manufactured economically.

Granite also shows its advantages over most construction metals when processed manually: By manually lapping guide and mating surfaces, flatness and straightness can be produced with micrometer precision, which in turn forms the perfect prerequisite for our precision machines.

#4 LOW RESIDUAL STRESS

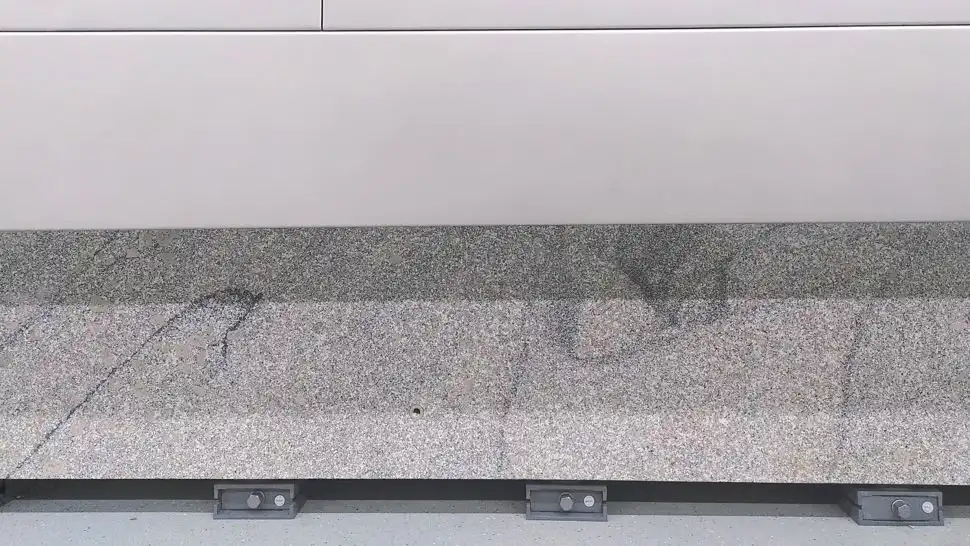

Ideally, a grinder should maintain its accuracy over many years. What could be a better basis for this than a machine bed that has almost no internal tension. Unlike the casting or welding of classic machine beds, the production of a granite bed does not create any tension in the material that takes years to dissipate. The rock has already aged in the earth’s crust for millions of years and the material stresses have been reduced. That’s why our granite-based machines are not anchored to the ground, but can stand freely on adjustable machine feet. By the way, unique structures often emerge in the granite bed, which can only be found in a natural product.

#5 SUSTAINABILITY

To get straight to the point: the granite blocks for our machines – like almost every raw material – are taken from nature and have to be transported and processed. However, the amount of energy required to produce such products is many times lower than that of common construction materials. When it comes to cast iron and steel materials, a huge volume has to be mined in mines and then processed into the end product in several temperature-intensive processes.

These steps are not necessary when using natural stone. Here, a block is broken from a quarry and then processed by machine and by hand. The finished machine bed is also not susceptible to corrosion, which makes our granite machines with standard stainless steel cladding very durable machines that maintain their precision for many years. Finally, the duration of use of a product also makes a decisive contribution to its ecological balance.

Comment & Notes

Please note, there are other well known machine tool builders, other than companies that manufacture precision measuring machines, that utilize natural granite as the basis to build a precision machine tool. For precision cylindrical grinding, consider Danobat and Overbeck as your solutions provider of natural granite based machines. For precision hard turning and/or a hard Turn/Grind combination, consider Hembrug as your competent partner.