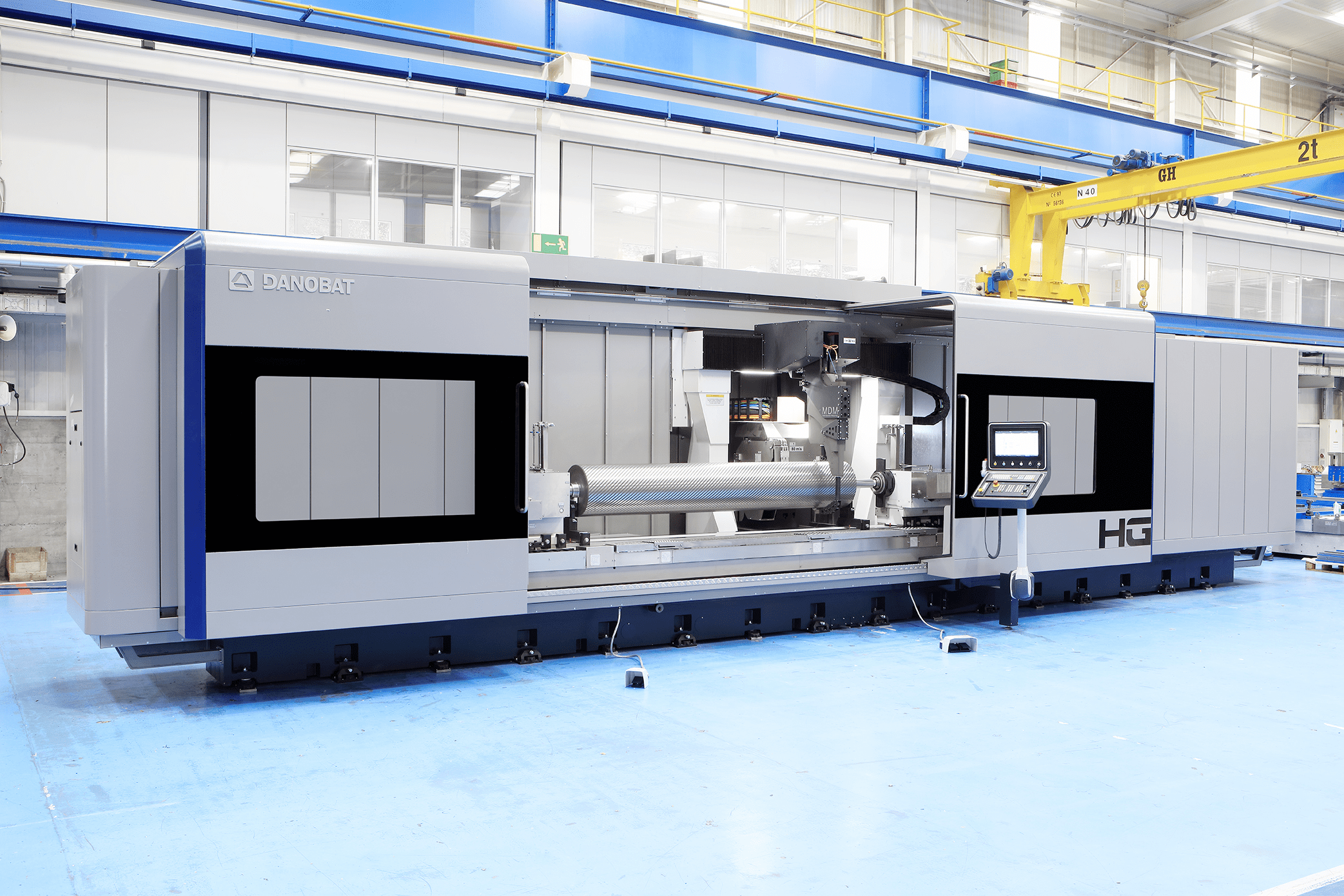

White Paper Excerpt I Courtesy of Danobat

Quote: “It takes a great deal of expertise to get the right balance of all components necessary to build a machine, or a system, that performs accurately, productive and reliable over time. The key is understanding the application, and then using the technologies that best gets the job done.” (Danobat R&D Team).

With a combined machine tool building history of more than 350 years, Danobat, Overbeck and Hembrug put together a highly relevant and valuable paper that will be important for anyone looking to evaluate a new CNC machine tool.

In its recently published paper, Danobat outlines the following, most crucial and most important areas and technologies that are important to precision machining:

- Machine Structure

- Geometry & Symmetry

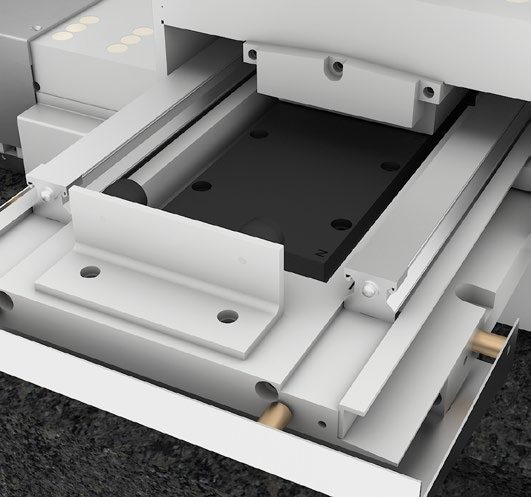

- Rigidity

- Thermal Stability

- Motion Control

- Axis Bearings

- Spindles

Download the article to discover the most important elements of a CNC machine that buyers should consider when evaluating CNC machining solutions here:

Precision is not simply the ability to machine a part accurately, but the capability to repeatably manufacture parts to exact/precise specifications over time. It is important to remember that no one feature will make a machine capable of precision manufacturing, but rather a variety of factors working in harmony will enable a machine to consistently produce parts within the most precise tolerances.