By Technica

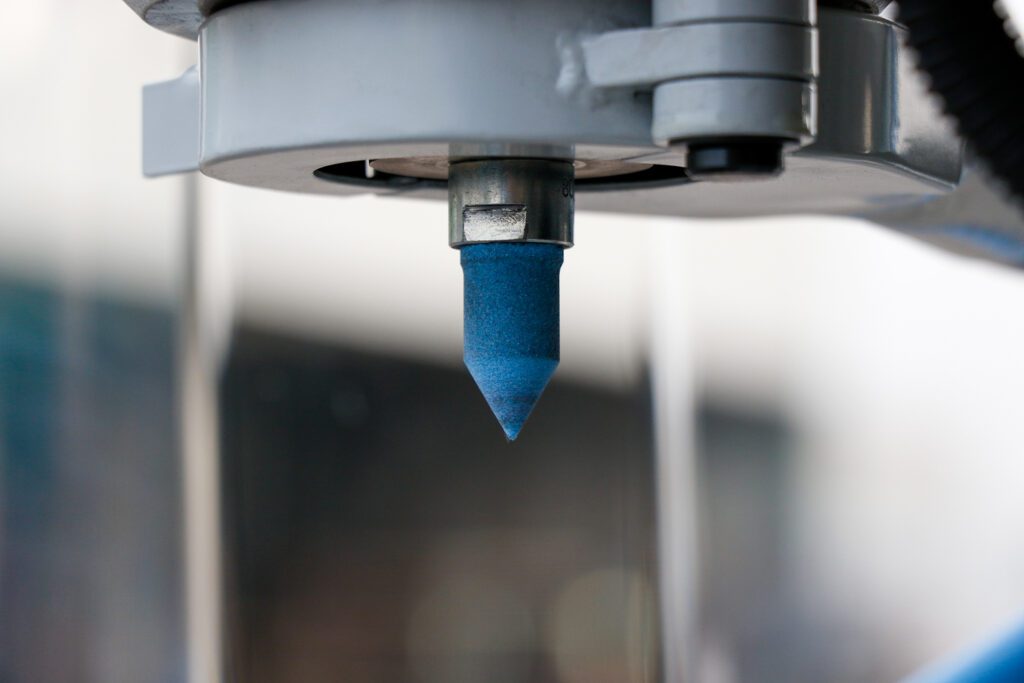

Zentroflex

Achieve sub-micron (< 1 µm) precision in grinding thanks to outstanding Swiss engineering, top-standard machine parts, and Swiss craftsmen’s workmanship with watchmaker precision.

Overview

A Series

The Zentroflex A–series center hole grinding machines are designed to deliver high-precision cylindrical grinding in the aviation, automotive, and machinery sectors for mass production.

Equipped with a 6-axis robot arm and servo motors on all axes of the machine, Zentroflex A series center hole grinding machines operate completely autonomously. All loading and unloading operations are performed by the robot arm.

Overview

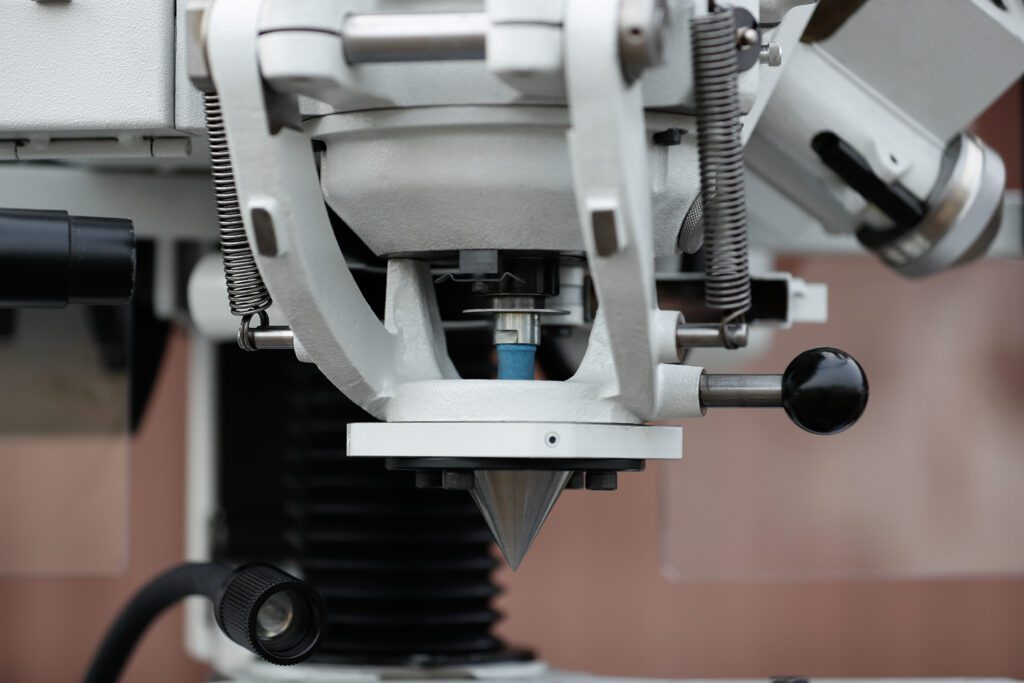

M Series

Zentroflex M series center hole grinding machines are designed to provide high-precision cylindrical grinding in the aerospace, automotive, and machinery industries.

Additionally, the Zentroflex M series is an ideal solution for recovering distorted parts after heat treatment or reducing cylindrical grinding costs.

Overview

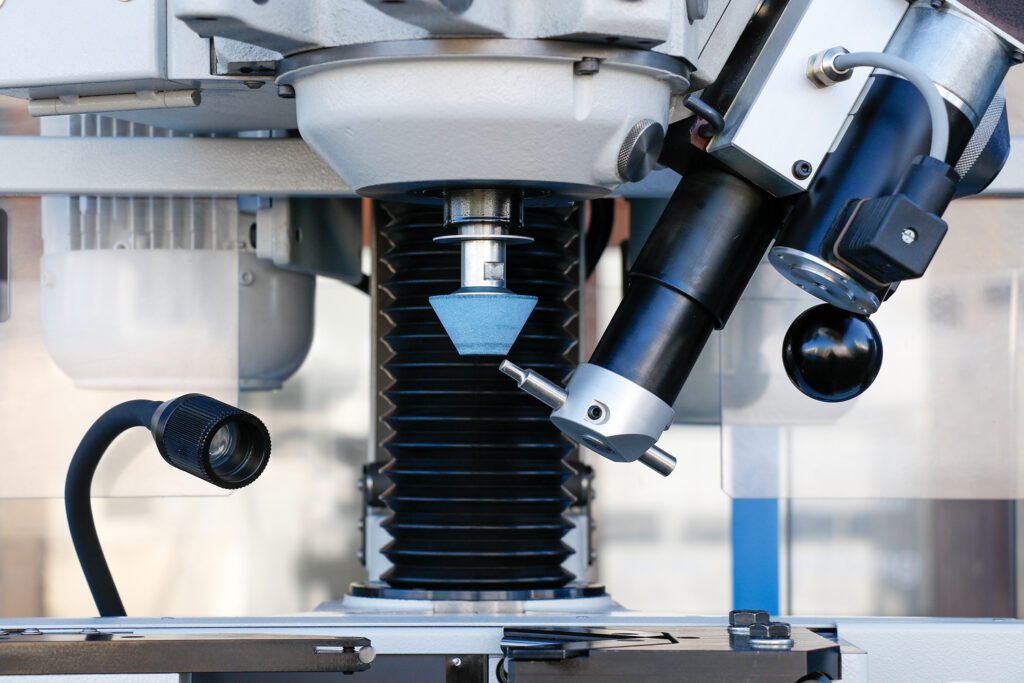

SA Series

In Zentroflex SA models, parts are automatically ground thanks to the servo Z-Axis movement and CNC control panel. Aside from routine operations such as loading, unloading, and changing the grinding cone, there is no need for a machine operator.

High-quality results are consistently achieved after grinding operations, regardless of the machine operator.

Technical data

Got a question?

Applications

Downloads

Get in touch

Find out more about our tailor-made solutions for all your grinding needs. Contact us today for a personal consultation and optimize your production processes with Rey Technologies.