By Danobat

Mikroturn®

The Mikroturn® machine series is designed to meet the highest requirements in the field of static and dynamic stiffness, thermal stability and geometrical precision.

Overview

Mikroturn® Baseline

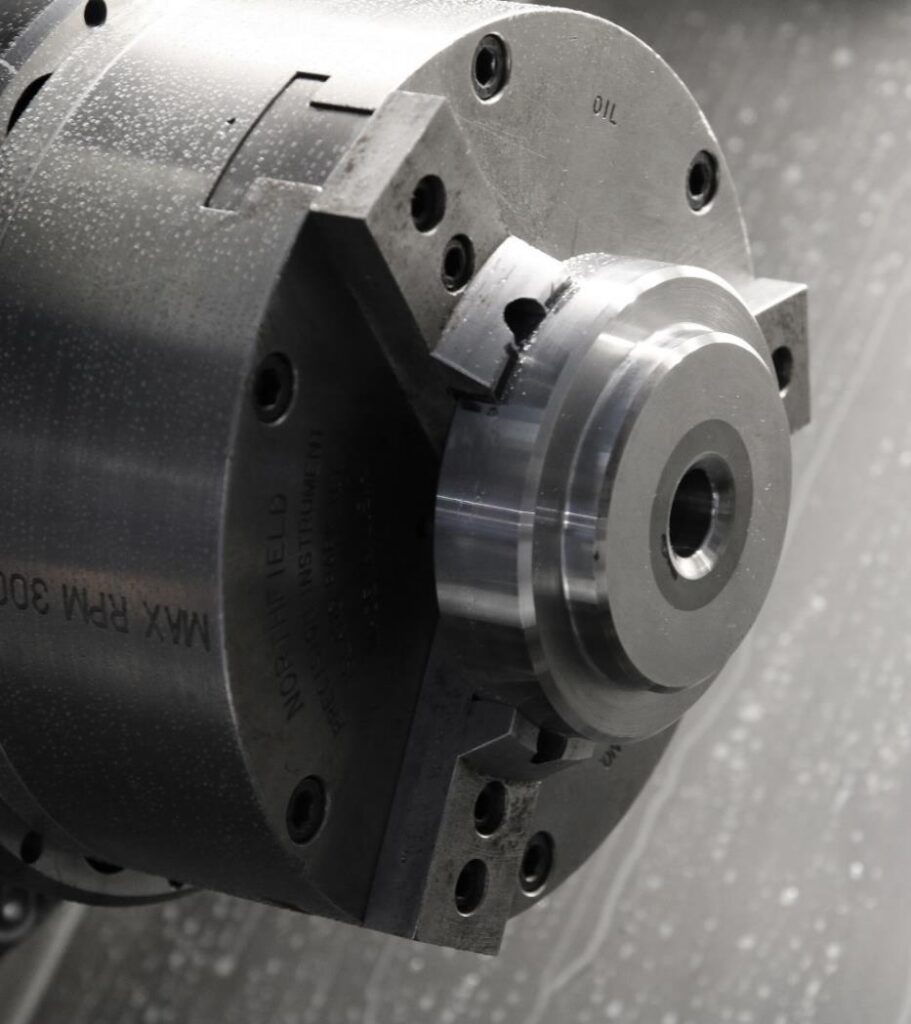

The Mikroturn® Baseline is an entry-level precision hard turning machine by Hembrug. Designed for workpieces up to Ø 15” (380mm), this machine boasts a natural granite base, fully hydrostatic linear axis, and a hydrostatic work head spindle.

Equipped with a Fanuc 0i control, the Mikroturn® Baseline delivers exceptional performance.

Overview

Mikroturn® 100

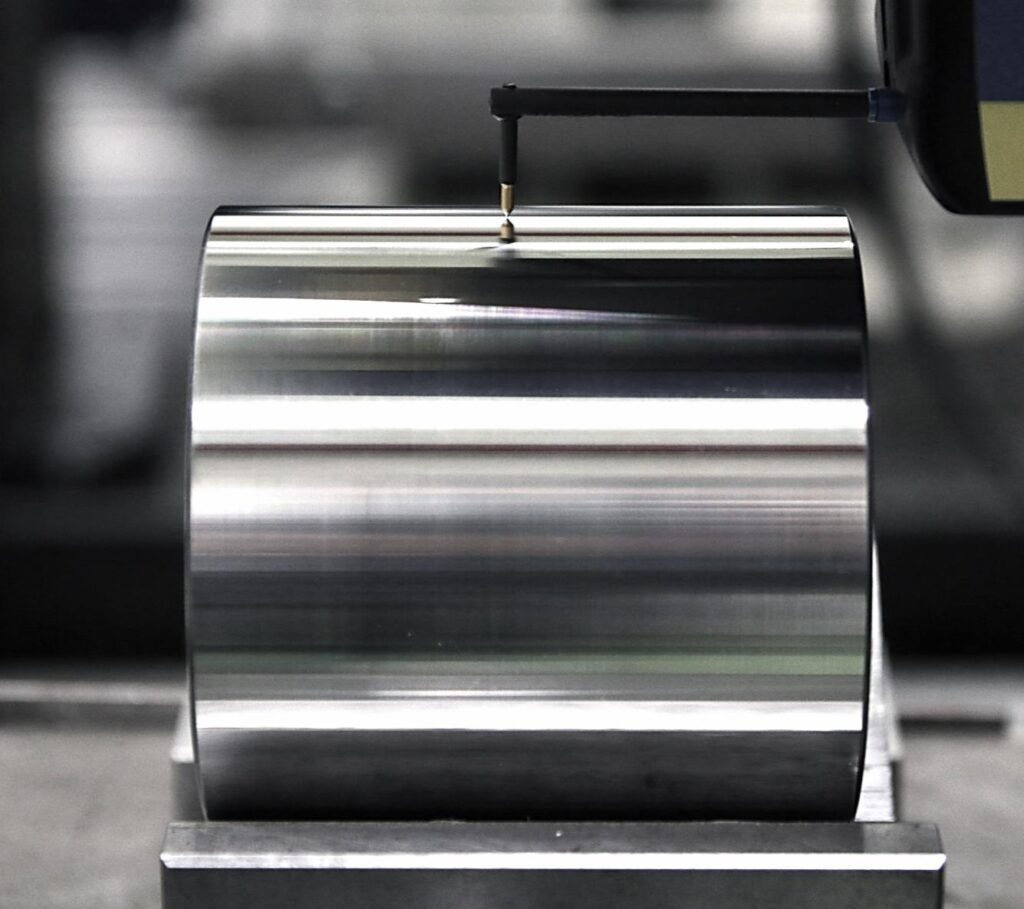

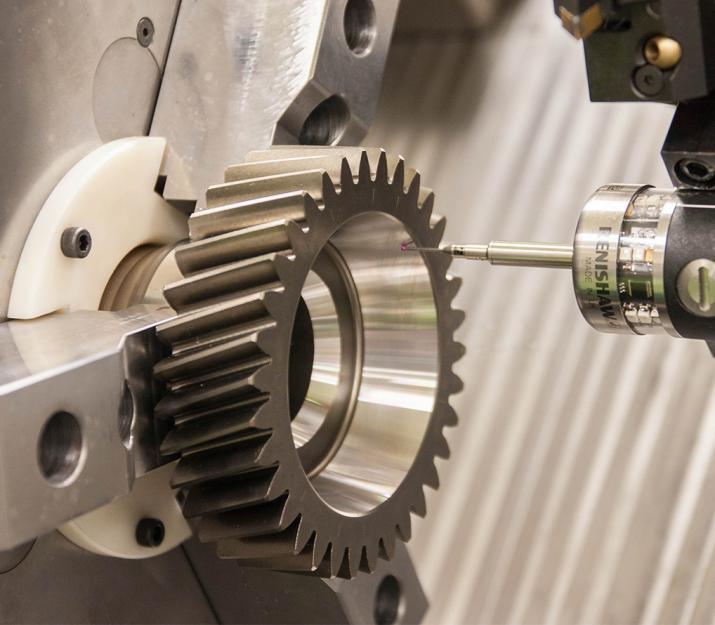

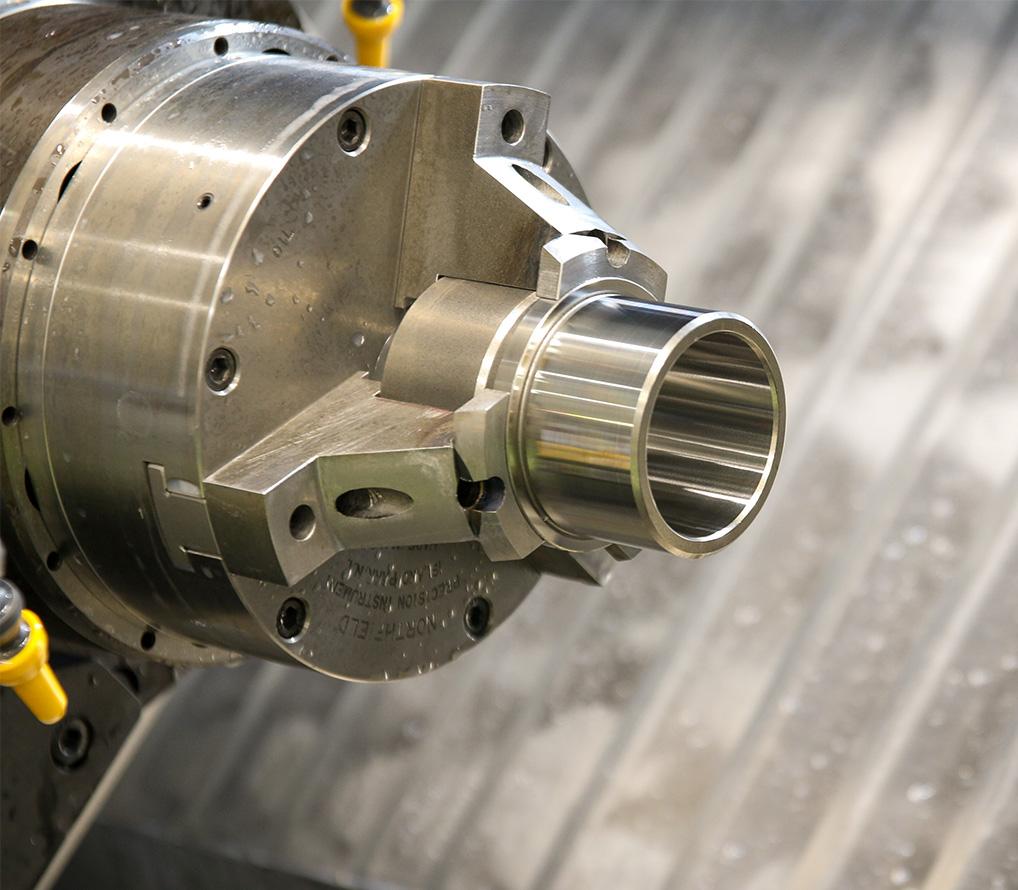

The Mikroturn® 100 is an ideal precision hard turning machine for small to medium-sized workpieces. It accommodates diameters up to 15 inches (380mm) or 7.9 x 13.8 inches (200 x 350mm) between centers.

Equipped with either a Siemens 840 SL or Fanuc 32i CNC control, the Hembrug 100 excels in processing a wide range of components, including ball screw nuts, bearing rings and rollers, hydraulic components, drive shafts, gears, and various mold & die components.

Overview

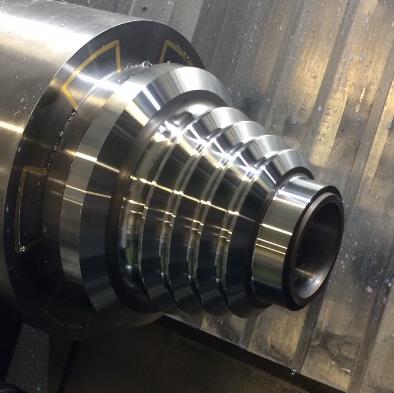

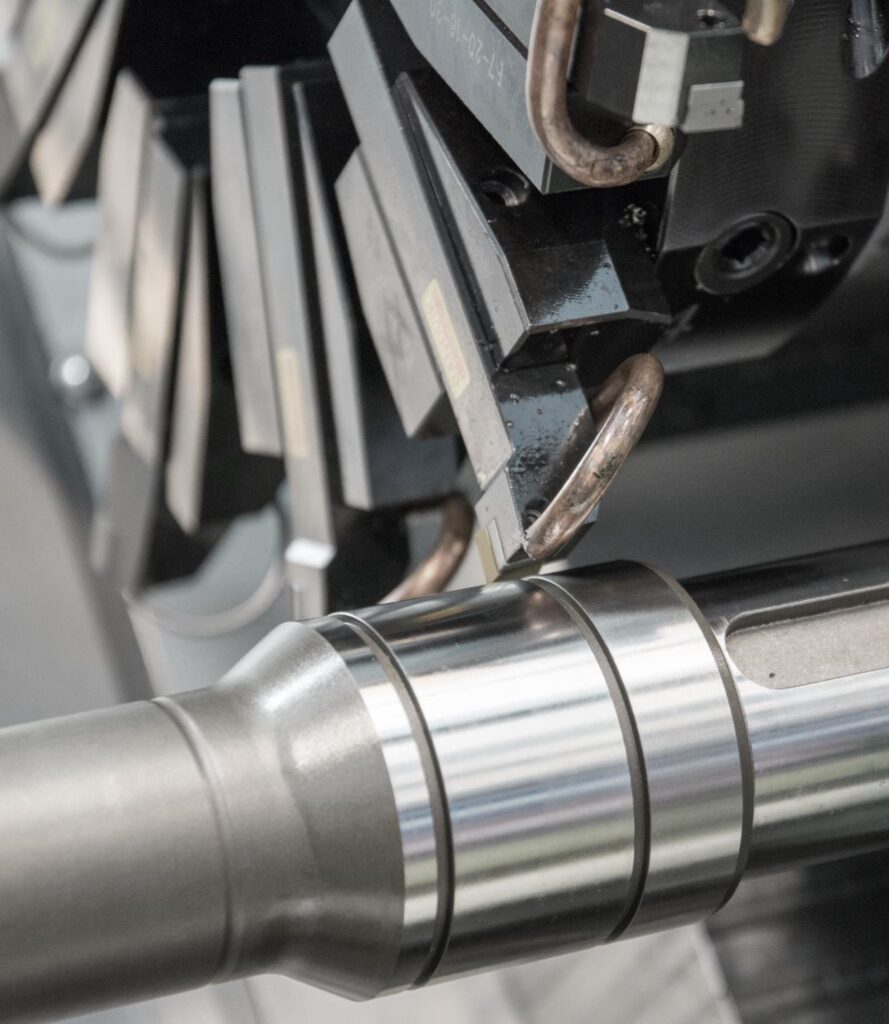

Mikroturn® 100 XLS

This precision hard turning machine handles part sizes of up to 350mm or 240 x 1000mm between centers. Equipped with cutting-edge technology and built for longevity, the Hembrug 100 XLS ensures exceptional performance in your machining processes.

Overview

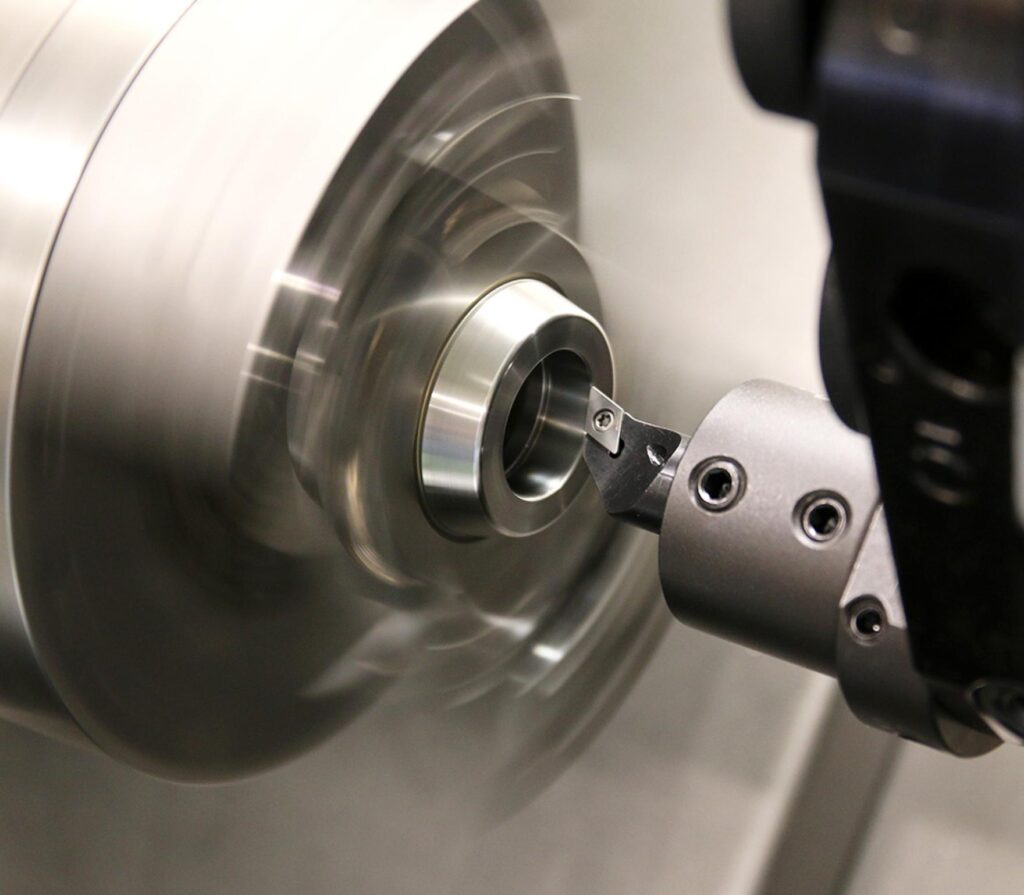

Mikroturn® 100 XLD

This precision hard turning machine handles part sizes of up to 24 inches (610mm). Equipped with either a Siemens 840 SL or Fanuc 32i control, the Hembrug 100 XLD ensures exceptional performance.

Overview

Mikroturn® Twin Spindle

The Mikroturn® Twin Spindle is designed for precision hard turning with dual spindles. It handles workpieces up to 4 inches (100mm) in diameter and 2.2 lbs (1 kg) in weight. The unique dual spindle design allows for production increases of up to 100%.

Applications

Downloads

Get in touch

Find out more about our tailor-made solutions for all your grinding needs. Contact us today for a personal consultation and optimize your production processes with Rey Technologies.